Soft Robotics

Robotics has become an increasingly popular field of study for engineers, with the use of robots becoming more widespread in a variety of industries. From manufacturing to healthcare, robots are being used to perform tasks that were previously done by humans. However, as the field of robotics continues to evolve, engineers are exploring new and unique applications for robots. In this blog, we will discuss a unique topic in robotics that engineers can explore: soft robotics.

Soft Robotics: An Overview

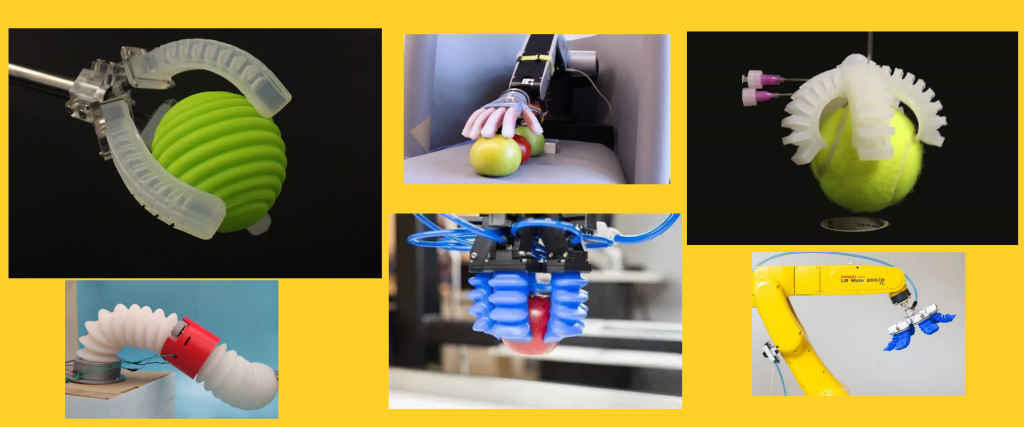

Soft robotics is an emerging field of robotics that focuses on the development of robots made from soft, flexible materials. Unlike traditional robots that are made from hard, rigid materials such as metal and plastic, soft robots are made from materials such as silicone, rubber, and fabric. These materials allow for robots that are more flexible and adaptable, with the ability to bend and stretch in ways that traditional robots cannot.

Soft robots can be used in a variety of applications, including manufacturing, healthcare, and exploration. For example, in manufacturing, soft robots can be used for tasks such as material handling and assembly. In healthcare, soft robots can be used for tasks such as surgical procedures and rehabilitation. And in exploration, soft robots can be used for tasks such as exploring difficult-to-reach environments, such as deep sea or space.

Designing Soft Robots

The design of soft robots presents unique challenges for engineers. Unlike traditional robots, which have a rigid structure, soft robots have a more fluid structure that can be difficult to control. To design soft robots, engineers must consider factors such as the material properties, the shape and size of the robot, and the control systems used to operate the robot.

One of the key advantages of soft robots is their ability to deform and adapt to their environment. This allows for soft robots to be used in a variety of applications where traditional robots would be unable to operate. For example, soft robots can be used in manufacturing applications where there is a need for robots to handle delicate materials or navigate tight spaces.

Controlling Soft Robots

Controlling soft robots presents a unique challenge for engineers, as the flexible nature of these robots can make it difficult to achieve precise movements. To control soft robots, engineers must use a variety of sensors and control systems that allow for precise control over the robot’s movements.

One approach to controlling soft robots is to use pneumatic systems. Pneumatic systems use air pressure to control the movements of the robot. This allows for precise control over the robot’s movements, as well as the ability to generate large amounts of force.

Another approach to controlling soft robots is to use shape memory alloys. Shape memory alloys are materials that can change shape when exposed to heat. By using shape memory alloys, engineers can control the movements of soft robots by heating and cooling the materials.

Applications of Soft Robotics

Soft robotics has a wide range of applications across a variety of industries. One of the most promising applications of soft robotics is in the field of healthcare. Soft robots can be used for tasks such as surgical procedures and rehabilitation. For example, soft robots can be used to assist with physical therapy by providing resistance and support during exercises.

Soft robotics also has applications in manufacturing. Soft robots can be used for tasks such as material handling and assembly. For example, soft robots can be used to handle delicate materials or navigate tight spaces that traditional robots would be unable to operate in.

Another promising application of soft robotics is in exploration. Soft robots can be used for tasks such as exploring difficult-to-reach environments, such as deep sea or space. For example, soft robots can be used to explore the ocean floor, where traditional robots would be unable to operate due to the harsh environment.

Conclusion

Soft Robotics is an exciting and rapidly developing field that holds immense potential for a wide range of applications. Soft robots offer several advantages over traditional rigid robots, such as enhanced flexibility, adaptability, and safety. They are capable of performing complex tasks with precision and can operate in unstructured environments, making them ideal for applications such as medical devices, industrial automation, and search and rescue missions. However, there are still many challenges to overcome in terms of power and control, and further research and development is needed to fully exploit the potential of soft robotics. With continued innovation and investment, soft robotics has the potential to revolutionize the way we live and work in the future.