ISIEINDIA Conducted 2nd batch of 15 Days training for Jalna ITI students on Auto Electrical & EV Assembly Technician program Sponsored by Jalna Janseva at Centre of Excellence

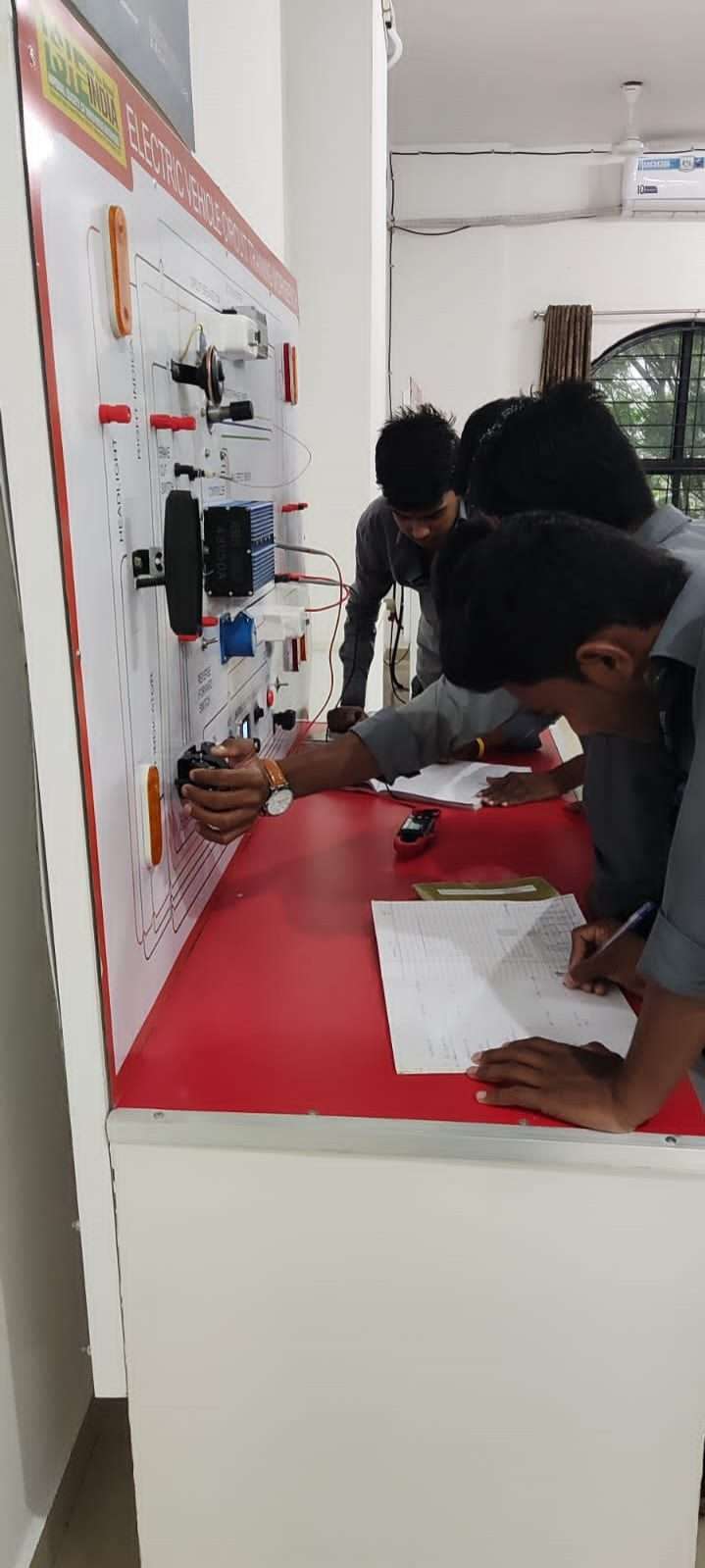

ISIEINDIA Conducted 2nd batch of 15 Days training for Jalna ITI students on Auto Electrical & EV Assembly Technician program Sponsored by Jalna Janseva at Centre of Excellence 7th September to 21th September 2022. In this training, 20 Students were given Hands on Training and all the topics were covered on daily basis.

TOPICS COVERED DURING THE TRAINING

DAY 1– Basics of automobile engineering

In this students were told about the history of vehicles, it’s components and system of ICE Vehicle.

DAY 2– Basic Fundamental of EV

There was a brief understanding about EV’s v/s ICE Architecture of ICE,EV, HEV Types of EV Opportunity and Available job roles for ITI/ Polytechnic in EV Sector.

Practical

- Demo of Components i.e. Motor , Battery , BMS , Controller etc. & Basic Introduction of Workbenches.

DAY 3– EV Machines

BLDC Motor hub, Motor Introduction, Motor Controller, Working of EV Machines were done practically by the students in front of there mentor.

Practical

- Dis-Asm of Motor and Controller (Hand on )

- Current & RPM Measurement in BLDC Motor , Hub motor and Induction Motor ( Workbench to be used – EV Machines).

DAY 4– EV Machines

Introduction Motor, controlling, working of EV Machines, the topic continued for 2 days.

DAY 5– EV Powertrain

Type of Drive Train section of component case study were done also the selection of motor, controller for 2 wheeler EV were the main topic.

Practical

- Mathematical Modelling of Drive Train 2.Circuit Diagram ( Workbench to be used – EV Circuit Training).

DAY 6– EV Battery and BMS

Types of Battery, Types of cell BMS, Battery Fundamental – Charging and discharging was made clear, SOC. Moreover, Experiments on EV Powertrain Workbench Motor Battery Loads Hall Effect Fundamental- Sensor Efficiency Fault Diagnosis were done practically.

DAY 7– EV Battery & BMS Testing

On next day, Procedure of Battery Pack Manufacturing( Cell Sorting-Cell EV Battery & Grading-Charging (Balancing) BMS Testing Welding of Pack, Battery Battery Ageing) was done.

- Battery Design – Mathematical foe 2 – wheeler.

- Experiement on EV 2 wheeler workbench.

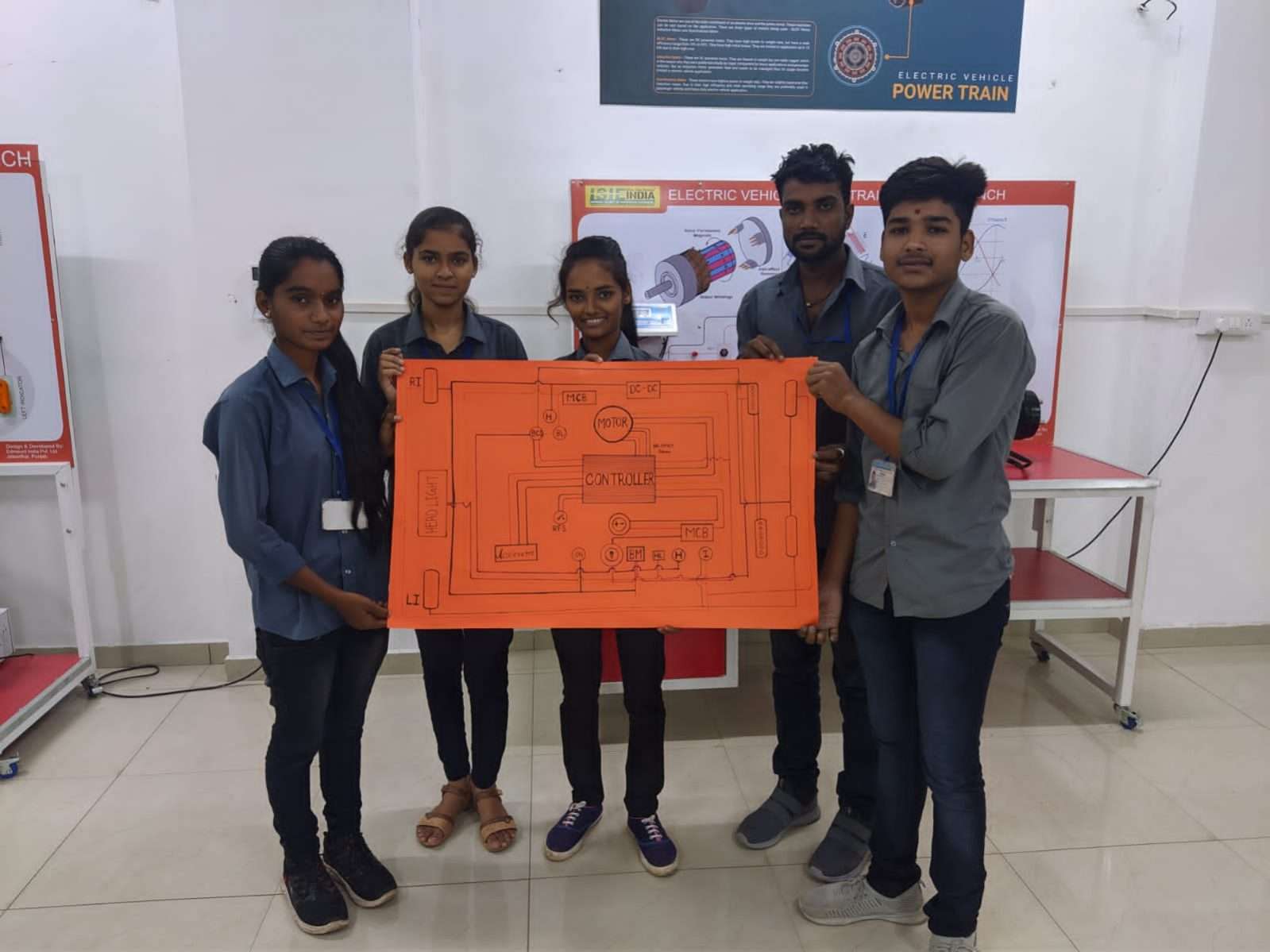

DAY 8– EV Circuit Diagram

Each and every point about EV was made to students. Next day of training was all about Vehicle Category 2 Wheeler Design and Safety Aspects Tests 2 W Component Testing (Horn Lights, Rear View Mirror Test. Field of Vision Test etc).

DAY 9– 2 W Hands on

Designing and testing of EV Circuit. Electrical Circuit Training & component test were made done practically by mentors in front of students.

DAY 10– Project

Retro fitment of 2 Wheeler Bike

The Training was successfully done, the students learened a lot about EV. ISIEINDIA is working with many Automotive Giants across the India and looking to connect with all the EV Industries to help them in training and development of their engineers, vendors, trainees etc.