How Electric Powertrains are Changing the Game for 2 Wheeler Industry

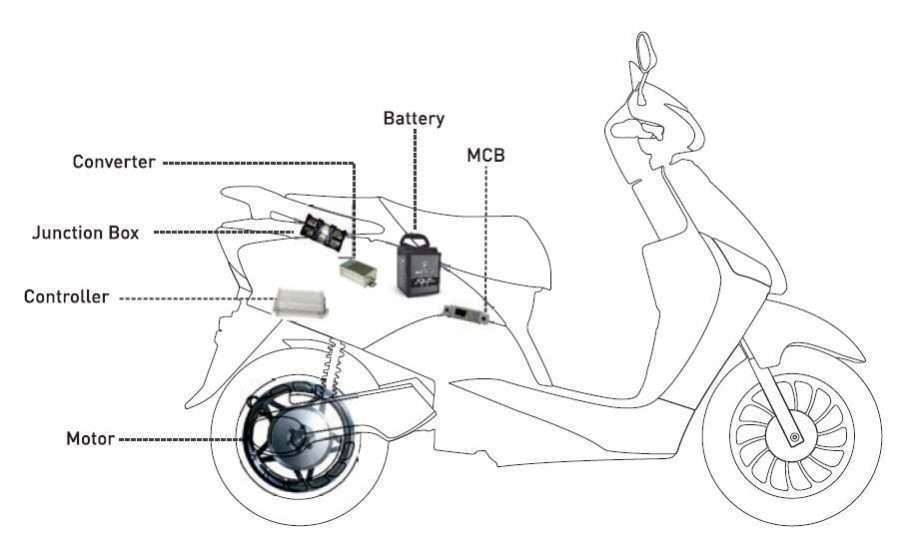

The average vehicle body provides structural integrity, whereas the electric motor concentrates on producing torque or force. The electric motor can be a brushless dc motor, permanent magnet synchronous motor, etc. the batteries will power these motors using a converter and a power controller (throttle).

What is EV Powertrain?

A car’s powertrain, to put it simply, consists of all the parts that propel the vehicle forward. In electric and hybrid electric vehicles, electric powertrain systems make up the bulk of the components that generate and transmit power to the road surface through wheel movement.

Components of EV Powertrain

The main elements of the scooters’ electric powertrain are listed below:

Engine:

Your car’s heart and the engine’s source of its power. Pistons, part of an engine, oscillate inside cylinders with the help of a crankshaft, which changes the oscillating action into a rotating motion.

Transmission:

The transmission, a crucial component of your scooter, ensures that the wheels receive the proper power. The information works similarly to a car’s gearbox in that it modifies itself in reaction to road conditions to distribute engine power to the wheels.

Battery:

Lithium-ion, nickel metal hydride, lead acid, and other battery types are available. Mainly the battery to parallel to the cells. Typically, the battery capacity is expressed in ampere-hours.

Power:

The power controller regulates the current flow in each winding phase. At the same time, the DC-to-AC converter (actually an inverter) provides the three-phase input needed by the motors for propulsion.

Typical Components of Vehicle Body

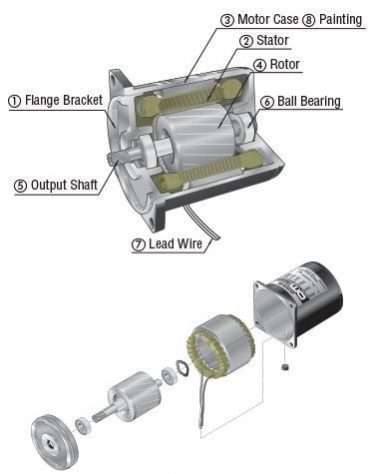

Depending on the application, the electric motor used for propulsion may have an inner or an outer rotor. Depending on the type of motor, these windings can carry AC or DC.

It uses the winding given in the slots to provide the necessary flux in the air gap. Direct application of battery power is possible, and a magnet installed on the rotor section allows for adjustment of the change created in the air gap. A typical motor with an inbuilt inverter frequently used for EV applications is the BLDC.

Rotor in EV Two Wheeler in Details:

The machine’s rotor, which typically rotates, is attached to a shaft that allows an external load to be connected or unconnected.

The motor is referred to as having an “inside rotor type” if the rotor is placed inside the rotor,

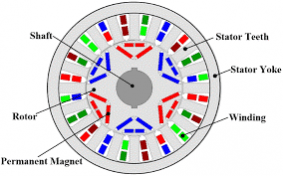

In radial flux machines where flux flows in that direction, such as the SM PM BLDC shown above,

Equation for torque is torque = k * (D)2 * L. (1)

Here, L is the machine’s stack length, and D is the rotor diameter.

Inner rotor-type radial flux engines typically have a smaller rotor diameter and a longer stack length than outer rotor machines. A two-fold increase in rotor radius will produce a four-fold increase in the machine’s output torque when employing external rotor topology.

Since the machine’s rotor diameter and stack length are growing, the force will also grow. Desirable in particular circumstances involving in-wheel EV applications with high torque and power density.