Get 200+ hours learning sessions, masterclass by industry experts & 20+ case studies

Exposure to global job opportunities with timely doubt resolution

Featured Programs for you

PG Certification in Hybrid Electric Vehicle Design and Analysis

Still Not sure?

Talk to our Expert Mentors

Transform your career with these

services

ISIEINDIA Benefits

With India's largest online higher education company, get 360 degree career support. mentorship from industry experts, networking opportunities, and more.

Lowest Price

Get the Industry Level content and curriculum at lowest rate possible.

Easy Lesson

Courses designed in such a way that it is easier to learn even when you are changing the domain

Industry Mentor

Interact with our Industry mentor & gain access to vast network of expert from all domain

Research Paper

Publish Research Paper from IIT on the selected domain of your choice

Doubt Resolution

Have any query/problem statement you need to be resolved we have a doubt session every weekend

Placement Assistance

Get informed about Vacancies (Internship/Job/Training Program) in the industry, exclusively for ISIEINDIA candidates.

Our Track Record

Because words aren’t enough, we let numbers do the talking. 🙌

300 %

Salary Hike

60 %

Average Salary Hike

80 %

Success Rate

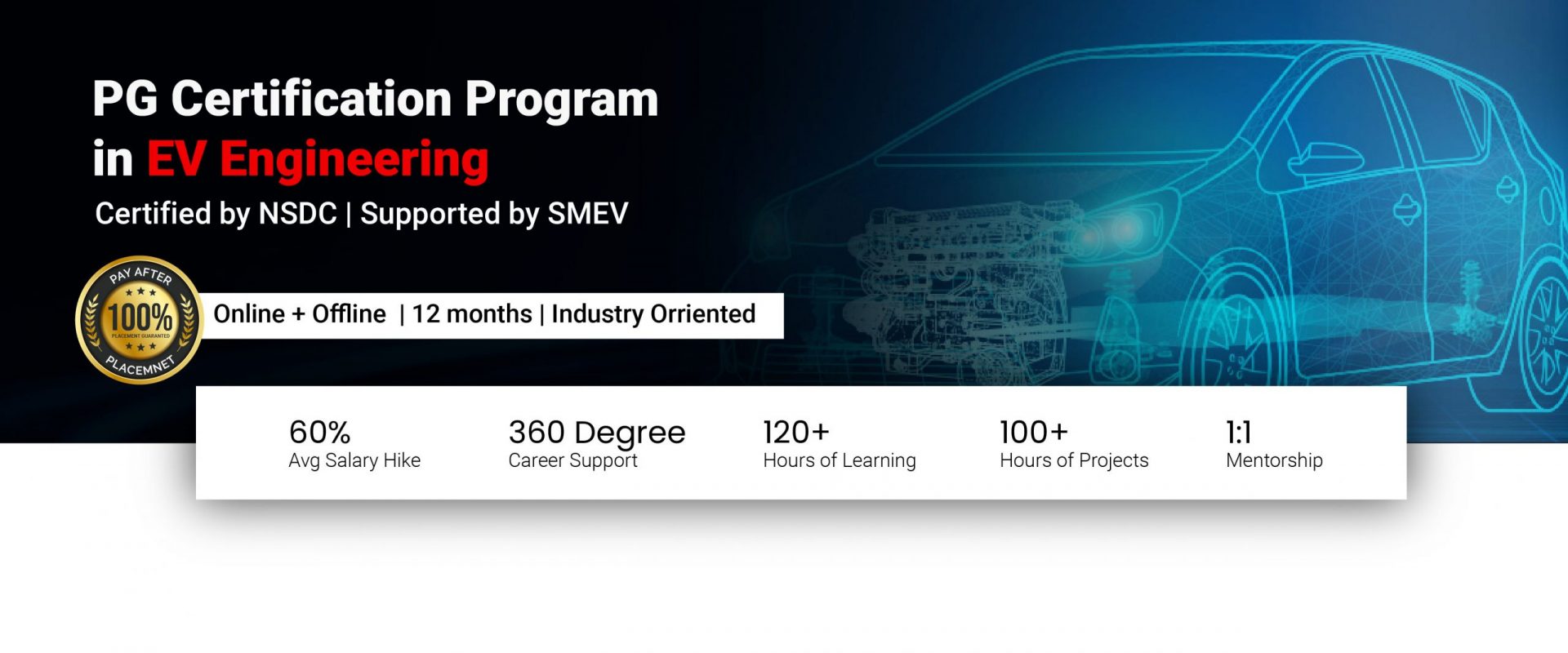

PG Certification Program in Electric Vehicle Engineering®

PG Certification Program is Unique and Exclusive program in Electric Vehicle Engineering® offered by India’s Leading Skill Base Educational Platform, ISIEINDIA. This Program is especially designed for engineering graduates.

This Program provides opportunity to learn without quitting your job and Up-Skill yourself for EV revolution in India. It’s a 1 year Degree program in association with Govt. Institutions, Top Private Universities (India/Abroad) etc.

Mode of Delivery: Blended (Online + Live (Expert Session) + hands on / Research Project)

Jobs and Career Opportunities in Electric Vehicle by 2025

It’s not all doom and gloom for electric vehicles. The industry continues to grow at a rapid pace. In the long term, consumer demand triumphs, as seen by recent industry advancements. For example, Tesla, the world’s most valued electric vehicle company, is planning to introduce its Electric vehicles in India by later this year.

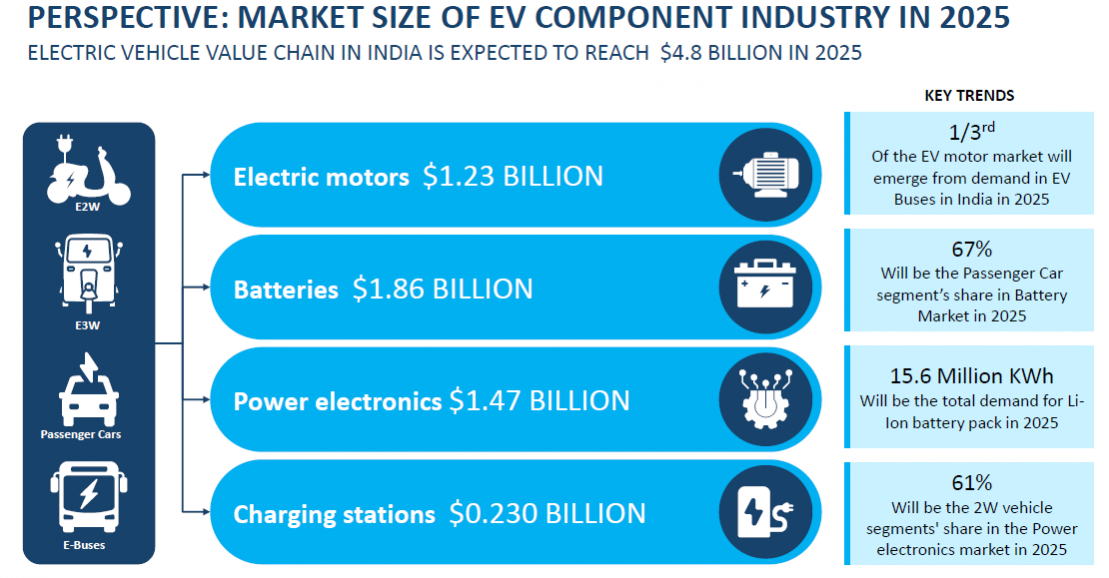

The EV industry will create over 10 million job opportunities in various domains such as designing, testing, manufacturing, wiring, charging infrastructure, sales, services, redesigning existing infrastructure, battery technology, and many more.

Read Full Report on EV Market and Job forecast by Niti Aayog Govt. of India

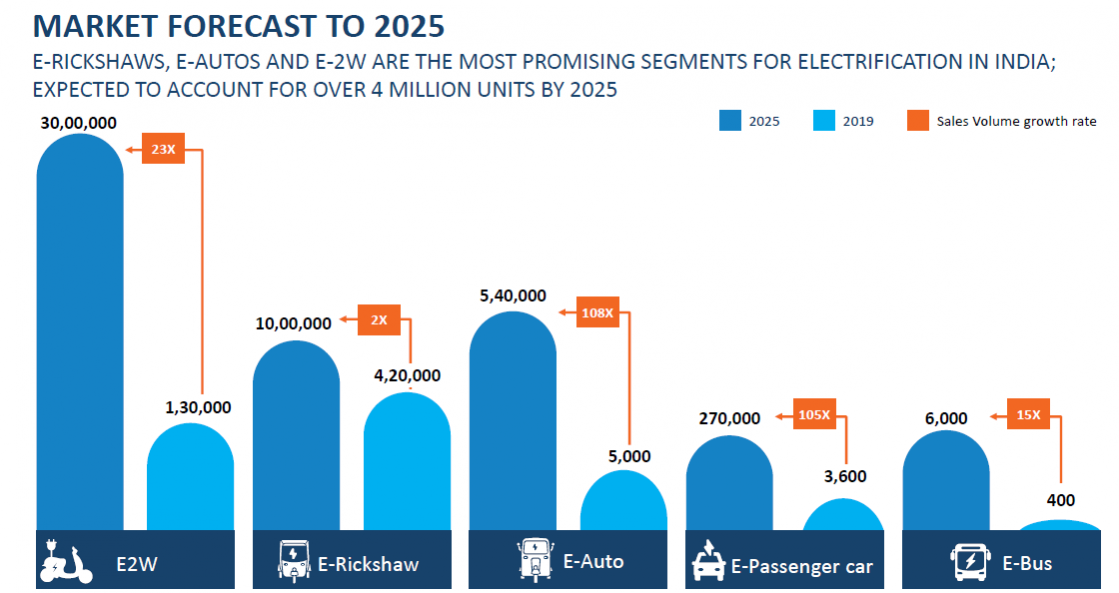

India is the biggest EV Market for Electric Vehicle as per the reports by 80% of 2W /3W Vehicles, 40% Passengers vehicles , 25% Private cars and 20% buses will be Electric in coming 5 years and will create 10M Jobs.

In a virtual roundtable on ‘Post COVID-19: Future of Electric Vehicles Global and India’ conducted by ETAuto, experts opined that the outlook for EV industry remains positive despite COVID-19 disruption with 30-35% of sales to be electric by 2025 which includes mild hybrid, full hybrids, plug-in, and battery.

List of Job Opportunities in the Electric Vehicle Industry

The EV industry is estimated to offer several job opportunities for skilled population. The significant profiles in the EV industry that require skilful employees are research, designing and development, manufacturing, vehicle maintenance, and infrastructure development.

Research & Development

- The electric vehicle industry requires a research and development team to acknowledge the latest technology and ideas that are trending worldwide to improve battery charging, recharging technology, fuel, or material sources.

- The research and development team conducts research and testing on electric vehicle technology. Usually, chemists and material scientists examine the battery life and analyze its performance.

- To make electric vehicles better than conventional vehicles, the researchers perform various tests to bring out fast recharging technology.

Design and Development

- The design and development sector includes everyone who helps in the initial vehicle modelling process to the final development process. Usually, engineers, software developers, industrial designers, technicians, and drafters work in this sector.

- They find out result-oriented and economical solutions that reduce vehicle costs. The design and development team strives to design vehicles accessible to all people, from rich to middle-class to poor financial families.

- Chemical, electrical, electronic, mechanical, industrial engineers, software engineers, developers, designers are highly demanded people for this job opportunity in the industry.

Electric Vehicles Manufacturing

- Manufacturing requires a considerable workforce and involves complex processes. Manufacturing workers would be taken from the conventional vehicle model industries. These people work in large sectors or plants outside the cities.

- The manufacturing team focuses on machine designing and production designing. They assemble workforce and machinery tools. The specialized people required in the EV manufacturing sector are machinists, industrial managers, machine tool operators, and equipment assemblers.

Maintenance Department

- These are nothing but the vehicle maintenance and repair works. Regular workers can also do these works. However, the electrical systems demand skilled electrical repair workers.

- The maintenance workers work on replacing and installing batteries based on the electric vehicle. Usually, mechanics and technicians are required for maintenance works.

Infrastructure Development

- As electric vehicles increase on roads, the necessity of charging stations increases. Electric vehicles need specialized charging infrastructure that incorporates battery charging and swapping systems.

- The government is planning to incorporate private and public charging points for easy access to the charging systems. In emergency cases, there would be several charging points away from your home and office. The infrastructure development team focuses on the charging point’s implementation and up-gradation of existing battery charging systems in various cities.

- Majorly, the power line repairers and installers are required along with few electricians to implement charging infrastructure.

Job Roles

- Powertrain

- Power Unit

- Charging

- Motor Structural Design Engineer

- Battery Pack Design Engineer

- Power Electronics Hardware Engineer

- Motor Control Systems Designer

- Battery Test Engineer

- Charging Control Systems Engineer

- Control Systems Designer

- Battery Packaging Engineer

- Charger Design Engineer

- Power Electronics Hardware Engineer

- Battery Management Engineer

- Charging Test Engineer

- Hardware Design Engineer

- BMS Software Developer

- Energy Supply Equipment Engineer

- Motor Testing Engineer

- Thermal Management Systems Engineer

- System Test Engineer