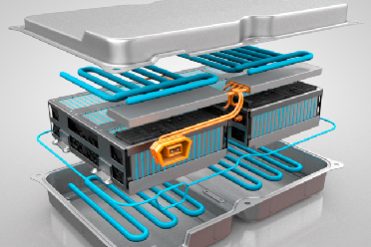

Learn Introduction to Cells and Battery Pack, Battery Pack Design, Cell Packing and Arrangement, Battery Safety Designs, Battery Pack Balancing, Battery Connectors, Battery Testing, Range Calculation accompanied with various recent case studies to attain the challenges set by the EV industries with Personalized Industry Mentorship, Career Guidance, and Placement Assistance and much more.

EV Battery Pack Design

- Description

- Curriculum

- Reviews

About the Program

Personalised Mentorship

Get mentored by an experienced EV Industry expert and receive personalised feedback calls for better career guidance.

Globally Valid Certificate

Get a Globally valid certificate and enter your workplace with confidence and assert yourself as a subject matter expert.

Student Support

Student support available 09 AM to 07 PM IST via email or call and get a response within 2 working hours.

Specialized EV Battery Pack Design

Certified by ASDC

Complete all the courses successfully to obtain the certification from ASDC.

• Globally Recognized Certificate

• Recommended program by SMEV, MSME and 17 + Automotive Industries.

Case Studies

Spot Welding vs Laser Welding

There are two major methods for combining cylindrical cells – spot welding and laser welding. Spot welding although cheaper has its own demerits, in this case, a study we understand the extent to which spot welding might affect cell life.

Swappable Battery Pack

The battery pack is used for providing the energy to drive. The battery pack recharge time is a major concern among consumers and manufacturers alike. To solve these various alternatives have been introduced such as – battery swapping. In this, we talk about the feasibility of swapping and design challenges.

Still Not sure?

Talk to our Expert Mentors

An Expert will reach out to you within 6 Hours

About EV Battery Pack Design Program

What portion of the vehicle cost is battery pack cost? For an average passenger vehicle, the battery pack covers almost 40% of the cost of the vehicle. Thus if somehow we are able to reduce the EV Battery pack size or the cost of it, then we may have a cheaper product. The issue over here is that – if we reduce battery pack size then it will reduce the range too, but if we change the cells and opt for cheaper ones then it may lead to safety concerns or performance deterioration.

In this course, we will be taking a look at similar problems, and try to understand the various parameters affecting the cell selection, sorting, EV Battery pack design, cell configuration, battery pack stability, etc, and design an optimized battery pack for a given range.

In this course, we will calculate the range of the vehicle given, and decide the cell configuration and arrangement. Selection of cells based on form factor, cell chemistry, range, powertrain requirements. This will lead to the design of battery packs and various regulations in place for battery pack testing.

Program Outcomes

Self Balancing for pack

Cell Sorting

Types of cells based on chemistry and shape.

Cell parameters and data sheet

Type of welding

Range calculation

Cell Characteristics for charge and discharge

ISIEINDIA Instructors

Learn from leading Industry oriented trainer, faculty and leaders

Our Expert Work At

Top companies from all around the world